Krono Flooring instructions

1clic2go pure Installation

Important notice: prior to and during the flooring installation, please read the installation instructions completely! The flooring procedure is accomplished according to ATV DIN 18365.

Follow these instructions precisely, in order to retain full claim privilege on the guarantee.

Various possibilities for installation are offered depending on the surface area to be used:

1. Quick and easy installation without glue

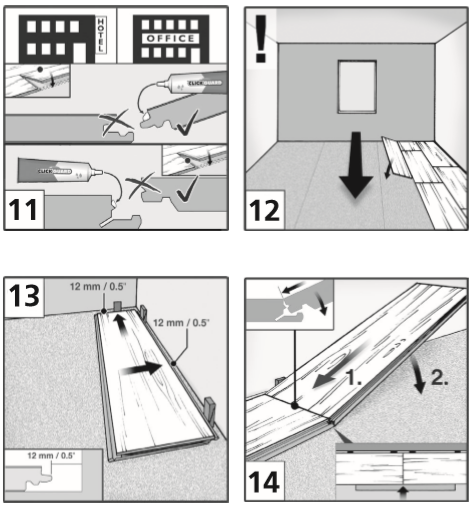

2. Installation with Click guard™: for the installation of krono original laminate flooring in commercially-utilized rooms, a sealing procedure must be carried out [11]. Click guard™ protects the flooring from the top down for the long-term against the effects of moisture. The floor lamination can be removed later and newly installed. When using Click guard™, please follow the installation instructions. In the event that a sealant is to be used, sufficient quantities of Click guard™ are to be applied to the tongue-spring side [11] (1 layer lengthwise and 1 layer for the width). The excess Click guard™ should be scraped off from the surface with a plastic spatula after max.15 – 20 minutes. Eventual remnants (residue) can be removed with household solvent cleanser.

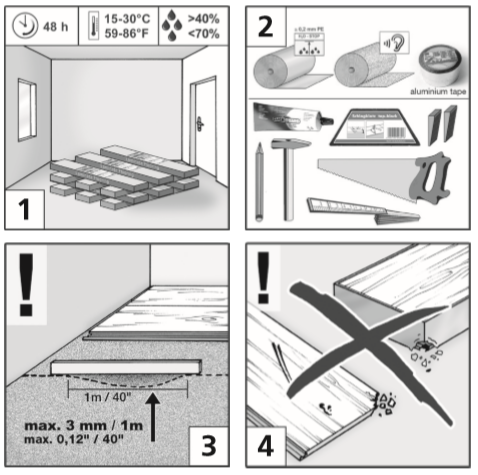

Preparation: Please store the packets 48 hours prior to installation under the same climatic conditions (temperature and moisture) as the actual installation process [1]. Important pre-condition for proper fitting and long-term durability of the krono original laminated flooring is a room temperature of 15 – 30°C / 59 – 86°F and a relative humidity of around 40 – 70%. Necessary Materials and Tools: polyethylene-foil, aluminum jointing tape, separation shims, fit-up aid, footfall sound insulation [2]. If necessary: Click guard™, joint sealing mass

The sub-surface that thekrono original laminate flooring will be applied to must be furnished in such a way that the laminate flooring can be installed as required by the manufacturer’s instructions. Appropriate sub-surfaces are, among others, mineral sub-surfaces (such as floor screed, concrete, asphalt), particleboard sheets and timber floor boards. The sub-surface must be absolutely even, dry, clean and stable. Floor irregularities measuring more than 3 mm per 1 meter / 0.12“ per 39.37“ length must be evened out by a professional (according to DIN 18202) [3]. The evenness of the sub-surface can be best ascertained by means of a straightedge or a spirit level. When installing onto a mineral sub-surface such as concrete, cement-screed, anhydrite-screed or flagstone (among others), a moisture measurement must first be carried out. The following remnant-moisture levels in the screed may not be exceeded, prior to installation:

- Cement-screed: with under-floor heating < 1,8% CM;

- without under-floor heating < 2,0% CM

- Anhydrite-screed: with under-floor heating < 0,3% CM;

- without under-floor heating < 0,5% CM

No offsets, steps or similar unevenness must be present. Construction dirt such as residues of render or plaster or similar must be removed completely. Cracks in the ground must be also considered alarming. In order to assert full claims for damages, the provisions of ATV DIN 18365 and § 4 para. 3 VOB/B must be observed.

Check the panels under good lighting conditions for irregularities. Boards with visible defects outside the applicable tolerances, such as deviations in height, gloss, dimensional and color, must be sorted out and replaced free of-charge [4]. For already-fitted or previously-worked panels, a reclamation claim from you is no longer possible.

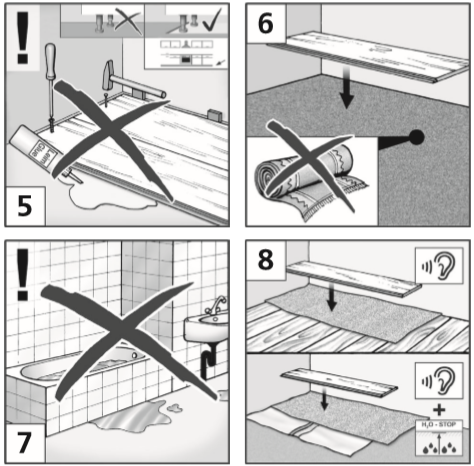

Krono Lamination flooring is installed under “floating” conditions and may not be glued, screwed, nailed, or in any other fashion fixed to the floor!

Carpet flooring must be removed and is not suitable as a sub-surface for the lamination flooring. Due to the carpeting lying under the lamination, problems arise when the krono original laminate is walked on in that a spring-motion occurs and considerable pressure is exerted on the lamination edges. This destroys the groove-tongue connection and leads to the formation of a gap. The carpet flooring must also be removed for hygienic reasons. Areas subjected to humidity can result in mold and bacteria forming [6].

Please note that this krono original laminate flooring is not suitable for wet-rooms (e. g. bath or sauna) [7].

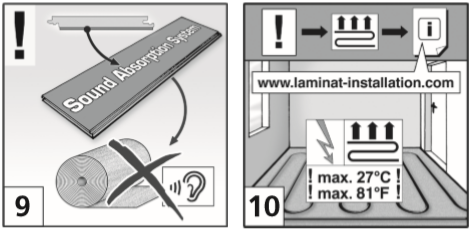

In the case of a wooden sub-surface such as installed sheets or floorboards, no polyethylene foil may be installed. Prior to installing the laminate flooring on a mineral-based sub-surface, (concrete, screed, etc.) it is crucial that a suitable vapors barrier sheet (PE-foil) is put down (with 1-2 centimeter /0.40“- 0.80“ 90° edging at the sides-like a shallow tub) as a protection against moisture. The tile channels are installed about 50 mm / 2“ overlapping next to one another and fixed with special aluminum jointing tape. On all substrates, a system-based insulation underlay is recommended to improve impact sound minimization. The insulation underlay is installed edge to edge, i. e. is not overlapping [8]. Make sure that the insulation underlay joints are not directly under the krono original laminate joints. If the laminate floor already has an integrated insulation underlay, then no additional insulation underlay should be used [9].

The use of underfloor heating (hot water / electric) is only possible if expertly laid and provided that the heating operates properly [10]. The supply and installation of the underfloor heating system must be state of the art and it must be commissioned by a specialist company in accordance with the relevant heating criteria. Accordingly, a signed heating-up and cooling-down protocol must be in place. Underfl oor heating must be laid and operated across the full area of the room. Partial underfloor heating is not permitted. A temperature of 27°C on the surface adjacent to the underside of the flooring should not be exceeded at any time anywhere over the area. Any complaints in connection with the operation or the installation of a floor heating system is excluded if the requirements described above are not met. Claims can be asserted solely within the scope of our general warranty and guarantee provisions. For underfloor with and without underfloor heating, the specialist installer must perform and record the necessary CM measurement prior to installing the floor. The following limit values apply to residual humidity:

- with calcium sulfate screed max. 0.5% CM without;

- 0.3% CM with underfloor heating

- with cement screed max. 2.0% CM without;

- 1.8% CM with underfloor heating

For floating installation, the thermal resistance of the krono original laminate floor and the insulating substrate must be observed. The total of the thermal resistance of all components must be ≤ 0.15m² K/W in accordance with the requirements of DIN EN 14041. When using the insulating materials which do not come as part of the range of accessories, any warranty is excluded in the case of floating installation on heating screeds with regard to compliance with the effective maximum permissible thermal resistance of the overall construction.

It is recommended that the panels be sorted according to the desired pattern lines and (if necessary) colour nuances prior to installation. You should start working with packages of krono original laminate flooring immediately after opening!

Installation: It is recommended that you lay out the panels in the direction of the length and the source of light [12].

For non-straight walls, you must first transfer the profile of the wall-line to the first row of panels and saw the panels accordingly. Measure, prior to installation, the spatial dimensions of the room as well. In the event that the fi rst row of panels proves to have a width of less than 5 cm / 2“, you must then evenly partition the remaining length (excess length) among the first and last row of panels in such a manner that both rows are cut to size with the same (symmetrical) panel-width.

Recommendation: For improved ease of installation, a system-based insulation underlay is recommended. If no such insulating base is used, then the hammer and hammering block should be used for secure transverse joint locking [20].

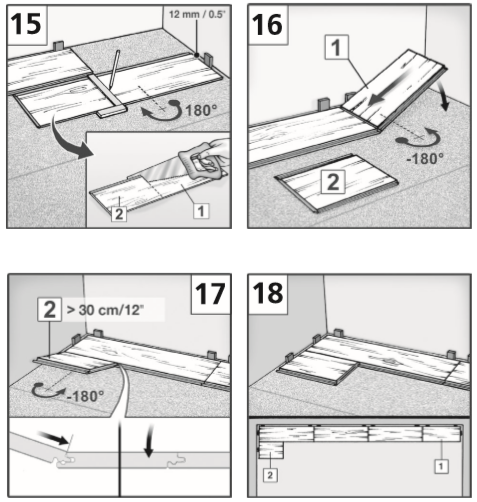

Begin your installation in the left corner of the room. Lay out the first panels with the tongue-spring side facing the wall and secure the edge separation (gap) with shims. It is important to retain a 12-15 mm / 0.5“-0.6“ edge distance (expansion gap) from the wall, heating pipes, posts, doorstop, etc. [13].

Insert a second panel with the facing edge (short side) at an angle of 30° into the groove profile of the previously laid panel [14] and then lay flat on the floor. Make sure that the longitudinal edges are aligned. Ensure that they are not offset and form a straight line. This is necessary to insert the panels without gaps into the longitudinal profile when laying the second row of panels.

Click in further panels until the end of the first row in the same manner.

Turn the last panel in the row [15] by 180° for adjustment / trimming; place the decorated side up next to the existing row (groove cheek to groove cheek) on the right side of the wall. Take an edge distance of 12-15 mm / 0.5“– 0.6“on the facing side into account. Mark and cut the panel lengths. The last panel of the 1st row is also inserted at an angle of 30° into the groove profile of the previously laid fi rst panel and then lays flat on the floor. Make sure that the longitudinal edges are aligned. Ensure that they are not offset and form a straight line.

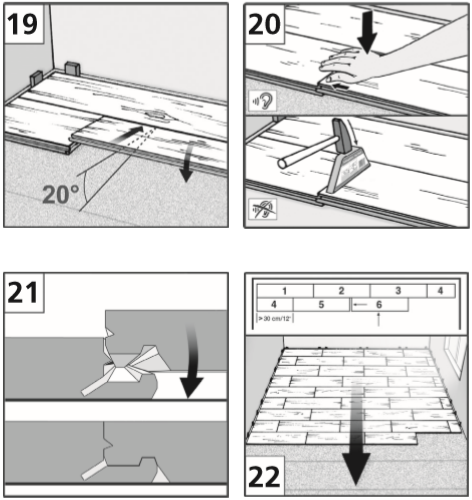

In order to avoid splintering of the edges, the decorated side should face down when using electrical jigsaws or hand-held circular saws. Otherwise, cut down from the top of the panel. Begin each new row with the remnants (at least 30 cm / 12“ in length) of the previous row.

Begin the second row with a half panel (length < 95 cm / 37.40“) or with this remnant (length > 30 cm / 12“) [17-18]. Insert the panel section length-wise in the groove profi ling in the fi rst row and lock it in place / bend it [19]. The transverse joint offset must be at least 30 cm / 12“ from row to row.

Place a second panel length-wise in the groove profiling of the panel area and push it to the left at an angle of 20° to the panel already in place [19]. Then bend it downwards and press from above until you hear an audible click [20, 21]. In doing so, ensure that the panel is inserted and guided cleanly through the longitudinal profile. If no system-related insulation underlay has been used, use a hammering block and a hammer [20] to lock the two panels.

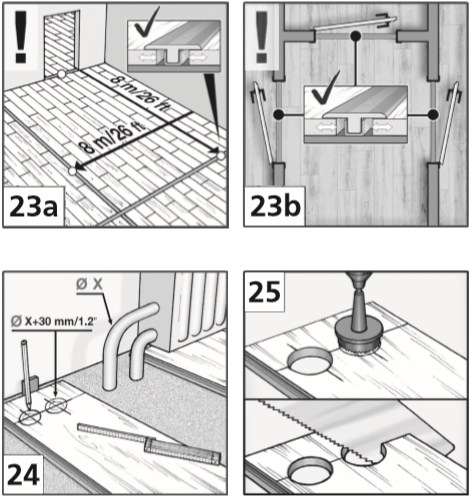

For installation surfaces with more than 8 meter / 26ft length or width, and for considerably angled rooms, expansion joints (at least 2 cm / 0.8“ wide) are necessary [23a]. This allows the floor to respectively expand or contract during climatic changes. Keep this in mind also when making overlapping installation from one room to another. In this case, the surfaces in the area of the door frame must be interrupted [23b]. Expansion joints can be properly masked with corresponding profiles. The movement gaps may not be filled with cables or other materials. Please observe the requirements of the ATV DIN 18365. Movement and edge joints in the ground may not closed with a form fit, or be impaired in their function in any way. The design of the movement joints must allow for the same movement options.

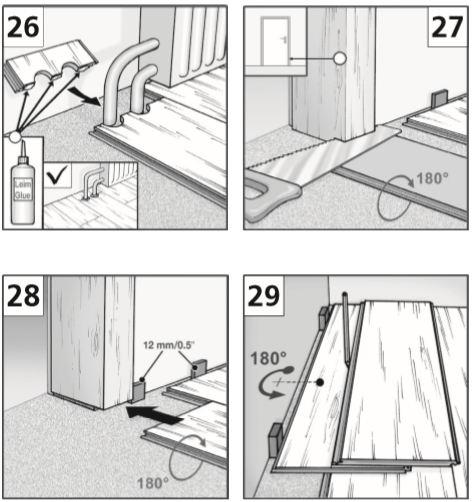

For heating-radiator pipes, holes that are drilled 3 cm / 1.2“ larger than the pipe diameter must be avoided. A “fitting piece” should be cut out, glued, ftted in and fixed in place with a wedge until the glue has dried. Then cover the recesses with a radiator-sleeve [24, 25, 26].

Wooden doorframes should be shortened enough that a panel with footfall sound insulation including 2-3 mm / 0.8“-1.2“ gap can fi t underneath [27, 28].

After installation, remove the separation wedges.

Cleaning and Maintenance

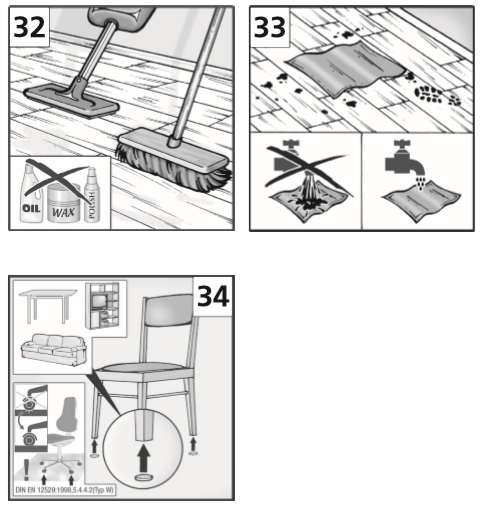

Remove non-sticking dirt by sweeping or with a vacuum suitable for hard floors [32].

For the on-going care, use only the wiping materials recommended by the manufacturer of the laminate. The following are not suitable for the treatment of krono original laminate flooring surfaces: polish and cleanser with treatment additives such as wax, oil, etc. The laminate flooring may not be polished [32].

Wipe up foot-prints and dirt with a thoroughly-squeezed and drip-free cloth. Standing water should be avoided in all circumstances [33]!

Special care should be taken regarding flower pots, vases, etc. that are standing on the krono original laminate. Use a water-proof support underneath the object.

Stubborn spots should be selectively cleaned and removed with a suitable cleanser spray or acetone. Do not apply additional sealant onto the krono original laminate flooring surface.

Attention! Protect the flooring from scratches or indentations! Use a sufficiently large dirt-magnet around the entry areas.

Furniture feet made of wood, metal or plastic must be furnished with felt protectors. Office chairs with soft rollers (DIN 12529) only are to be used [34], or lay down a commercial quality protective matt. With consideration of these instructions, you will extend the longevity of your krono original laminate flooring and be able to retain complete claim to the guarantee particulars.

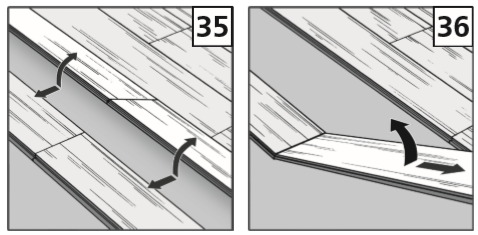

Lifting or removing It is possible to replace or remove panels that have been laid as floating flooring in living areas and commercial areas without causing damage by first releasing the whole row along the long side by angling it to free it from the locking mechanism [35]. Next, the panels, while lying flat on the floor on the head side, should be bent on the narrow side and released from lock [36]. Please be particularly diligent and careful when undertaking this work in order to avoid damaging the tongue-and-groove sections.