What is Spc(Stone polymer composite floors)?

Many types of flooring are suitable for all types of houses, wood, laminate, and Stone polymer composite(spc flooring). more and more people want to use spc flooring for their houses since 2019. Now, Spc flooring is one of the most popular flooring product types in the world.

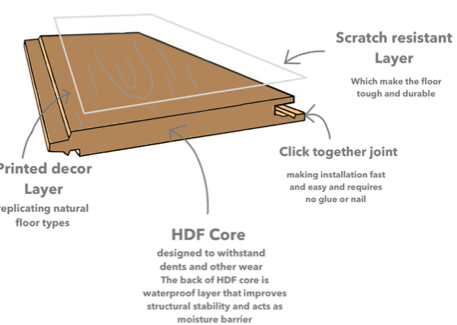

SPC flooring Structure

Stone Polymer Composite, is composed of a limestone core, PVC dust, and a stabilizer. Since the composition focuses heavily on the limestone factor, we find that SPC has a rigid, dense core. With that incredibly dense core, SPC(Stone polymer composite) is more impact-resistant than its LVF counterpart, Wood Polymer Composite (WPC). In addition, It is made up of four layers:

Top Layer: The upmost layer is composed of a stain-resistant and waterproof UV Ceramic Bead.

Second Layer: the transparent wear layer that helps provide added protection without affecting the color of your product.

Third Layer: The third layer is the high-definition design.

Fourth Layer: The fourth layer is the rigid core that helps hinder any expansion and contraction.

Understand more about SPC Flooring

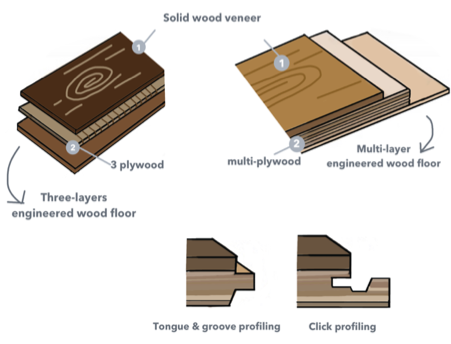

Edge jointing systems

Our Stone polymer composite floors (SPC flooring) edge jointing systems have sufficient strength and provide sufficient locking force to prevent separation. It should be noted that strength, fit, ease, and speed of installation vary substantially between locking systems.

At the board ends the profile end of the board is installed to be angled on installation into the end joint of an installed board before marrying the edge joint, known as ‘angle-angle’ installation. With this method, tapping blocks are often required to ensure tight board edge joints

Subfloors

All subfloors should be sound and structurally comply with relevant NZBC construction standards (i.e. the supporting timber or concrete which may also have been overlaid with tiles or resilient flooring etc.).

Any determined problems with an existing subfloor or overlaid product (for example, squeaks in an existing timber or sheet subfloor or tile fixing integrity) may affect the performance or appearance of the installed laminate floor and should be corrected prior to floor installation.

All subfloors need to be sufficiently flat to accept floating flooring systems. This is even more critical with floating floors than adhesive fixed floors. If the subfloor is not sufficiently level, then this can lead to board squeaking or separating. We highly recommend tolerance where deviations do not exceed 2mm beneath a 1m-long straight edge (or 3mm beneath a 1.5m-straight edge). Where concrete subfloors are not sufficiently flat, leveling compounds and grinding to level the subfloor needs to be undertaken. With timber and timber-based subfloors, packing of joists and sanding of sheet subfloors may be necessary.

Locality and dwelling environment

Conditions of about indoor temperature 18 to 30ºC and 50 to 60% relative humidity are considered comfortable SPC flooring conditions. When the flooring temperature is over 30ºC, the high temperature is greater expansion.

Prior to laying the floor, a period of 48 hours acclimatization is recommended. When acclimatizing SPC flooring, the boxes remain in their plastic wrap, unopened, for 48 hours so that the flooring can become accustomed to the temperature within the dwelling.

Allowance for expansion

The living room with many windows under high-temperature conditions SPC flooring would expand more in its length than the room with no windows. Consequently, there will be a difference in the movement of the two-floor areas where they adjoin. To prevent the one-floor area from having an adverse effect on the other, it is necessary to separate the two-floor areas. Therefore, control joints need to be added and this is referred to as compartmentalization.

The next aspect to consider is the overall size of the room or floor area that may extend from one room to another. Manufacturers’ installation instructions require intermediate control joints if the floor area is over a certain size. This may be, say, 10m in length and 8m in the width of the floor, which in some instances may influence decisions regarding the laying direction. It is important, however, that the specific manufacturer’s instructions are followed with regard to this as a different manufacturer may, for example, specify 10m in both floor width and length of the floor.

What do your need to notice for install SPC flooring?

Thoroughly examine the flooring prior to installation for a grade, color, finish, and quality. Ensure adequate lighting for proper inspection.

SPC(Stone polymer composite) products are plastic which has a benefit in them being moisture resistance and therefore not subject to dimension change with humidity, however, they are subject to dimensional change with changing temperature which similarly needs to be attended to at installation.

It was indicated that SPC(Stone polymer composite) products expand and contract depending on the temperature. If the temperature rises then the flooring will expand in both width and length, and the contrary is that a lowering in temperature will cause the flooring to contract. The greater the variation between summer and winter, the greater the seasonal movement that will occur and therefore the need for trims within the floor.

SPC flooring is NOT SUITABLE for a Strong sun-light environment room and wood sub-floor.

Wood sub-floor may Let’s SPC flooring cupping or warping if sunlight is strong, Please avoid direct strong sunlight to SPC flooring if subfloors are plywood. The curtain is really helping.

Strong sunlight will take temperature rises, then the flooring will be expanding on both width and length, and SPC (Stone polymer composite) will be cupping, bulk or warping, or bulging up. Please avoid direct strong sunlight to SPC flooring.

If you should be installing Stone polymer composites in a strong sunlight room we are recommending leaving over 15mm /10meters on each side of the flooring expansion and curtain.

When purchasing flooring, we recommend adding 5%-15% to the actual square meters needed for cutting allowance and to compensate for culled material.