Understanding Engineered Timber Flooring

Engineered timber flooring combines the classic appeal of solid wood with enhanced stability and durability, making it a popular choice for both residential and commercial spaces.

What is Engineered Hardwood Floors

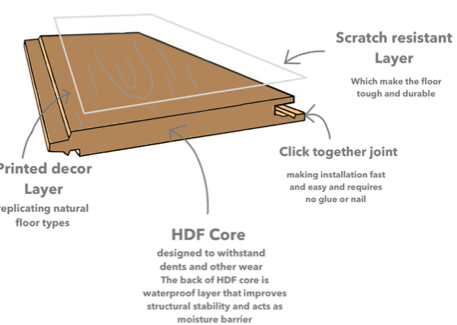

Engineered hardwood floors consist of a decorative layer of solid timber, known as the face lamella, bonded over multiple layers of other timber. This construction provides stability that counters the natural tendencies of wood to expand and contract with changes in humidity. Engineered floors can be installed as floating floors, directly glued to a subfloor as an overlay, or in some cases, fixed as a structural floor.

The board construction varies significantly across products, generally falling into two categories:

Three-layer construction: A face lamella over a core block layer and a stabilization layer.

Plywood base construction: A face lamella over a plywood base, providing excellent stability and resistance to warping.

Installation Methods

Direct Adhesive Fix: This method involves gluing the flooring directly to the subfloor, providing a firm feel underfoot and suitability for higher humidity environments.

Floating Installation: Floating floors are not fixed to the subfloor. Instead, they rest on an underlay, and the boards are fixed to each other, offering a softer feel underfoot.

Edge Jointing Systems

Engineered floors come with various edge jointing systems, including traditional tongue-and-groove (T&G) and glueless interlocking systems. While T&G profiles are suitable for both glued and floating installations, glueless systems are designed primarily for floating floors but are increasingly being used for direct adhesion.

Engineered wood is subject to natural color variations within a species, meaning no two packs of flooring will be identical. This variation is part of the natural beauty of wood flooring. Customers should be made aware of these variations and encouraged to blend boards from different packs during installation to ensure a harmonious look.

Wood floors can change color significantly when exposed to natural light. This can result in noticeable differences between the in-store sample and the newly installed flooring. It is crucial for retailers and consumers to understand this potential for change to manage expectations effectively.

The grade of engineered wood flooring refers to the size and number of visible features, such as knots and gum veins. These features vary between species and are not necessarily defects but characteristics that give the wood its unique appearance. Grading is often specific to manufacturers and can vary widely.

Not all engineered floors are suitable for every environment. Factors such as humidity and temperature must be considered when choosing the right product. For instance, floors installed in coastal areas or regions with high humidity require products specifically designed for those conditions.

Before installation, ensure that the building is weather-tight with all wet trades completed and dried. Proper drainage systems should be in place to prevent water accumulation, which can affect the flooring.

Engineered wood flooring may require acclimatization to the installation environment, depending on the manufacturer’s recommendations. This process aligns the moisture content of the wood with that of the installation site to prevent warping or distortion after installation.

A suitable subfloor is crucial for the successful installation of engineered flooring. Whether floating or directly adhered, the subfloor must be flat, clean, and free of contaminants that could impair adhesive bonding. Deviations should not exceed 3mm under a 1m straight edge for floating floors and a 3m straight edge for direct adhesive applications.

Engineered floors require expansion gaps to accommodate natural movement. This is particularly important in larger or differently shaped areas where differing expansion rates could cause sections of flooring to interact unfavorably.

Moisture barriers, such as polyethylene sheeting, are necessary, especially for installations below ground level or in areas with high ground moisture. This barrier prevents moisture from seeping up and damaging the flooring.

Engineered timber flooring offers the beauty of real wood with added stability and resistance to environmental changes. Understanding its construction, installation requirements, and how it reacts to different environments can ensure a successful and lasting installation. Proper planning, awareness of natural variations, and adherence to manufacturer guidelines are key to maximizing the lifespan and appearance of engineered wood floors.