About Laminate Flooring at Floorco

Floorco is renowned for its extensive range of laminate flooring, importing distinguished collections from top brands such as Krono Original, BerryAlloc, and Atwood Laminate. Our laminate products, known for their durability and aesthetic appeal, consist of multiple layers fused together to create highly resilient and attractive flooring solutions.

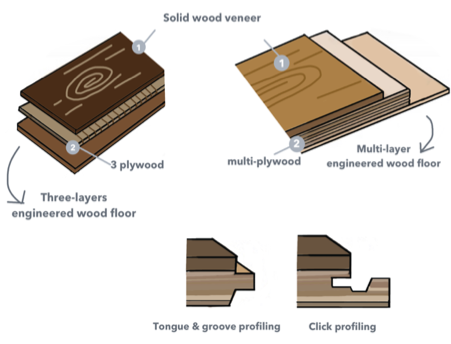

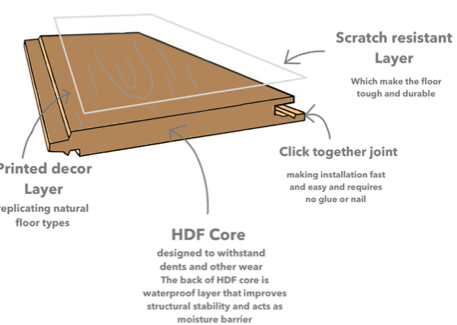

Laminate Construction

Surface Layer: This is the top wear layer that protects the floor from scratches, stains, and wear, ensuring longevity.

Decorative Layer: Positioned just beneath the surface layer, this decorative layer provides the visual appearance, mimicking natural wood, stone, or creative designs.

Core Layer: Also known as the substrate, this layer adds stability and density to the laminate flooring, providing the necessary support.

Backing Layer: The base of the laminate floor, this layer helps in balancing the board and prevents any form of warping, ensuring the floor remains flat and intact.

Laminate flooring at Floorco includes advanced edge jointing systems designed to enhance the durability and ease of installation. These systems, such as Unilin, Uniclic, Forma-Lock, Kwik-Fit, Lock&Fold, and JustClic, feature patented designs that provide a strong, seamless bond between boards. Each system is engineered to maximize the locking strength required to prevent the planks from separating, which is crucial in maintaining the integrity and appearance of the floor.

Installation Techniques:

This method involves inserting one end of a laminate board at an angle to the adjoining board and then flattening it down to lock it into place. It requires precision and can often benefit from the use of special tools like tapping blocks to ensure a tight and secure fit.

Proper installation of laminate flooring begins with a well-prepared subfloor. It is essential that the subfloor be clean, dry, and level to avoid any future problems such as squeaking or separation of the laminate planks. The standard practice is to ensure that any deviations in flatness do not exceed 2mm under a 1m-long straight edge, or 3mm under a 1.5m straight edge. Some manufacturers might have more stringent requirements depending on the product specifications. For concrete subfloors, it may be necessary to sand the surface until it meets the required level of flatness. With timber or timber-based subfloors, adjustments such as shimming or sanding the joists may be required to achieve an optimal surface for installation.

Moisture is a major concern with concrete subfloors, as it can lead to distortion or buckling of laminate flooring. It is imperative to ensure that new concrete slabs are adequately dried, which typically takes four to six months, depending on environmental conditions. Older slabs should not be assumed to be dry and may require additional measures to protect against moisture. This includes the use of a polyethylene plastic sheet, which should be at least 0.2 mm thick, with overlaps taped to create a moisture barrier that extends up to the walls and around any vertical fixtures.

The environmental conditions in which laminate flooring is installed can significantly affect its performance. The ideal temperature range for laminate flooring is between 18 to 25ºC, with relative humidity maintained at 50% to 60%. However, outside of this range, precautions should be taken to accommodate more extreme conditions. Low humidity can cause the laminate to shrink, while high humidity can lead to expansion. To mitigate these effects, it is recommended to acclimatize the flooring in its packaging within the installation environment for at least 48 hours, allowing the material to stabilize to the indoor conditions.

Appropriate planning for expansion is crucial when installing laminate flooring, particularly in larger or irregularly shaped areas. Compartmentalization using control joints can prevent interaction between different sections of flooring, allowing each to respond independently to environmental changes without impacting the adjacent area. This is particularly important in areas where the dimensions or orientation of rooms may cause differential expansion or contraction.

During manufacturing, a certain level of tolerance is allowed in the dimensions and appearance of laminate boards. These tolerances accommodate minor imperfections such as slight warping or edge damage, ensuring they do not affect the floor’s overall functionality or aesthetic. Quality control processes are rigorous, ensuring that each board meets the standards required for performance.

By adhering to these guidelines and standards, Floorco ensures that our laminate flooring installations are not only beautiful but also durable and long-lasting, providing our customers with value and satisfaction that endure over time.