Stone Polymer Composite (SPC) Flooring

SPC (Stone Polymer Composite) flooring has emerged as a premier choice for residential and commercial spaces globally since 2019. Known for its robustness and versatile aesthetics, SPC is increasingly preferred over traditional flooring options like wood and laminate.

The composition of SPC flooring centers around its dense core, which is primarily made from limestone mixed with PVC dust and stabilizers.

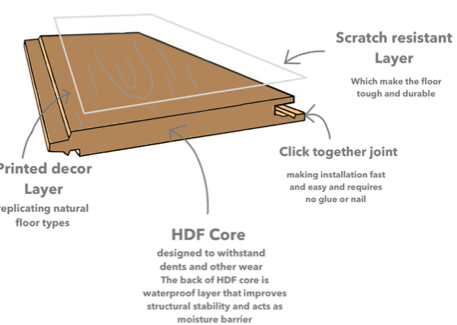

Top Layer: This is a UV ceramic bead layer, providing stain resistance and waterproofing to protect against daily wear and tear.

Second Layer: A transparent wear layer that shields the floor from scratches and impacts without obscuring the color and design beneath.

Third Layer: The decorative layer offers high-definition designs that replicate the natural aesthetics of wood, stone, or abstract patterns.

Fourth Layer: The core layer is where SPC flooring stands out. It prevents the planks from expanding and contracting under normal environmental changes.

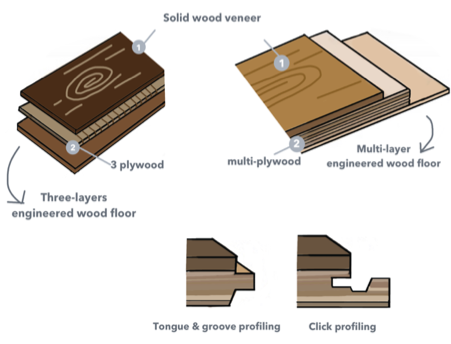

SPC flooring incorporates sophisticated edge jointing systems designed to ensure a tight and seamless installation. These systems, including popular options like ‘angle-angle’ and ‘drop-lock,’ provide a strong locking mechanism crucial for maintaining the alignment and integrity of the floor. Each jointing system has its own set of characteristics tailored to enhance the strength, ease of installation of the flooring.

Adhering to New Zealand Building Code (NZBC) standards, SPC flooring requires a well-prepared subfloor that is structurally sound. Potential issues with existing subfloors, such as squeaks or compromised tile integrity, must be resolved before installation to ensure the flooring performs as expected. It is critical that the subfloor is level, with deviations not exceeding 2mm under a 1m straight edge, to prevent issues like board squeaking or separation.

SPC flooring is designed to thrive in conditions ranging from 18 to 30ºC and relative humidity levels of 50 to 60%. High temperatures can cause more pronounced expansion. To manage this, a 48-hour acclimatization period in the packaging is recommended prior to installation. This step allows the flooring to adjust to the indoor climate, mitigating potential expansion or contraction post-installation.

The design and installation of SPC flooring must account for environmental and structural variances, especially in rooms with significant sunlight exposure or varying humidity conditions. Control joints are essential for separating different floor areas, particularly where large expanses are involved. Manufacturers typically advise on the placement of control joints based on the total area and dimensions of the flooring, ensuring each section can move independently without affecting the others.

Prior to laying SPC flooring, it is crucial to inspect each piece for consistency in grade, color, finish, and overall quality. Adequate lighting is necessary during this inspection to identify any potential defects. Due to its composition, SPC flooring is less prone to moisture-induced changes but can react to temperature fluctuations. Installation strategies should therefore include allowances for expansion and contraction, particularly in environments exposed to significant temperature variations.

SPC flooring is not recommended for areas subjected to intense sunlight or installed over wood sub-floors without adequate precautions. In environments with strong sunlight, SPC can expand excessively, leading to issues like cupping, warping, or bulging. To mitigate these effects, installing curtains to block direct sunlight and ensuring a sufficient expansion gap are advised.

When purchasing SPC flooring, consider ordering an additional 5%-15% beyond the calculated area to accommodate cutting waste and potential defects. This extra material ensures that installation can proceed smoothly without unexpected shortages, allowing for a professional finish.

SPC flooring offers a aesthetically pleasing, and practical solution for modern flooring needs. Understanding its structure, installation requirements, and how it interacts with its environment is key to ensuring it delivers both performance and beauty in any setting. Whether for a home or a commercial space, SPC flooring stands out for its robustness and ease of maintenance, making it a smart investment for long-term use.