Editor: Terry Shi

The founder of FLOORCO, with a strong industry background and substantial supply chain resources.

Engineered Wood vs. Solid Wood Flooring: Which is Right for You?

Choosing among the various available types of flooring options for your home is one of the major decisions that you ever have to make, and an outright dilemma for most people when there comes a choice between the two.

Both engineered wood and solid wood have their positive and negative aspects that will be discussed below in greater detail. By having operated in the hardwood flooring industry for decades, we have been able to help our customers make this choice by answering some of the most common questions and concerns they had.

We go over the difference in engineered wood versus solid wood flooring, pros, and significant cons of each before finishing up with what’s trending right now in wood flooring so you may have a comprehensive guide for a well-informed decision.

What is Engineered Wood Flooring?

Engineered wood flooring is the modern solution to have beauty like real wood, with enhanced durability and versatility. Unlike solid wood, which is made from a single piece of timber, engineered wood is composed of several layers. The top layer, known as the wear layer, is manufactured from real hardwood.

The layers below it are composed of some plywood or high-density fibreboard. This layered construction imparts superior stability on engineered wood, which is less prone to expansion, contraction, or warping of solid wood caused by fluctuating levels of moisture and temperature.

Multi-layer Engineered Wood Flooring vs. Three-layer Engineered Wood Flooring

Once one decides that engineered wood flooring is the route to take, one needs to understand the difference between multi-layered and three-layered construction, which will make a great difference in the performance, durability, and feasibility of the product in all circumstances.

Multi-layer Engineered Wood Flooring:

Construction: This is an engineered wood flooring that is made of five or more layers of material. These will include the top hardwood layer, multiple layers of plywood, or high-density fibreboard.

Each layer of the material is positioned such that the grain runs in a completely different direction from that of the adjacent layer. This way, it brings out better strength and stability in the construction of the flooring.

Advantages: Additional layers in multi-layer construction give the floor very good dimensional stability, making it especially resistant to variations in humidity and temperature.

This makes the product eminently suitable for installation below ground or in areas where damp may be a factor-something not confined to kitchens, even those with underfloor heating, when other products may be vulnerable. The increased stability also decreases the likelihood of warping or buckling over time.

Use Cases: Multi-layer engineered wood flooring is well suited for large areas or rooms with high traffic intensity, as it has extra layers to hold up better to wear and tear.

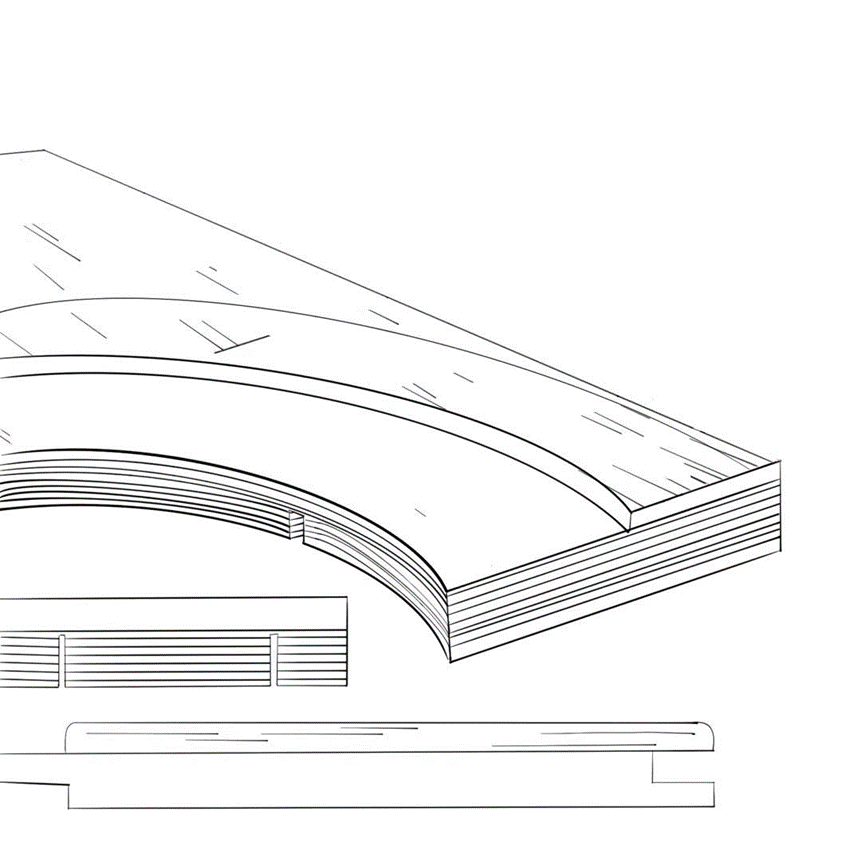

* Multi-layers Engineered wood flooring

Three-layer Engineered Wood Flooring:

Construction: Engineered wood flooring is of this type, having three layers in its construction: a topmost layer, a core layer that is usually made from softwood like spruce and pine, or a stabilizing bottom layer.

The layers are also arranged to cross each other’s grains for added stability, though less than multi-layer alternatives.

Advantages: Three-layer engineered wood flooring represents a good compromise between stability and cost. It will not be as strong as multi-layer flooring, yet it still provides quite a lot of resistance against the environmental impact when compared with solid wood.

It has also been known to weigh less, which makes it easier to carry and install.

Examples: Three-layer flooring is a popular product in many residential installations where radical environmental conditions are not a factor; it’s a nice, economical alternative for a homeowner who wants the look of hardwood but does not want the extra expense of multi-layer construction.

This difference between multi-layer and three-layer engineered wood flooring is in turn one of the reasons that explains the importance of correct selection regarding a certain housing condition.

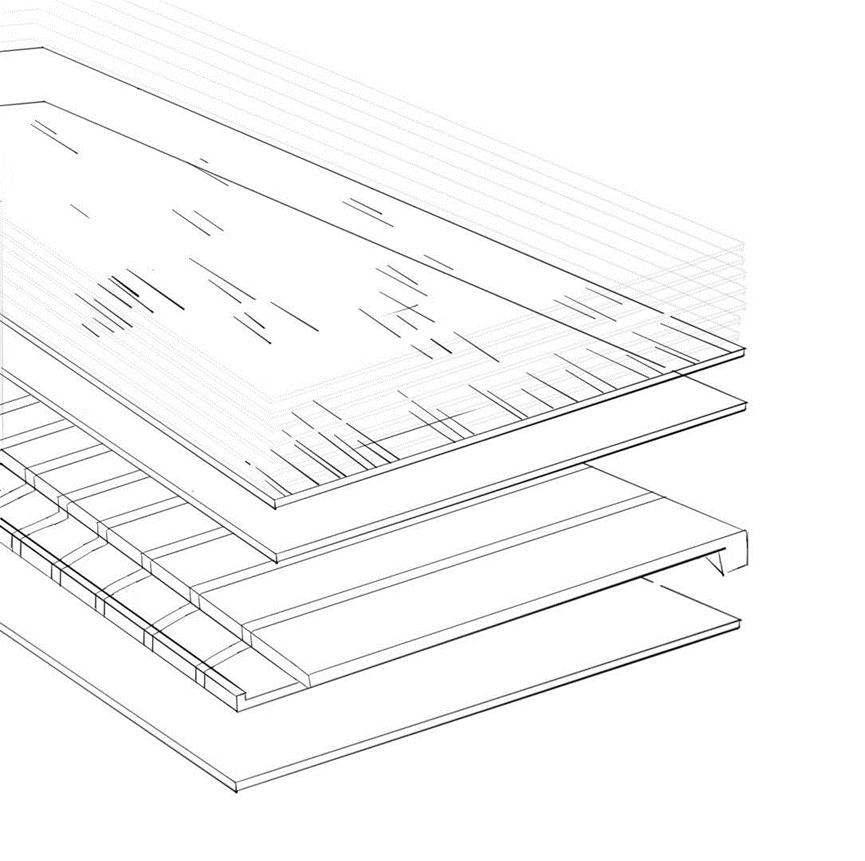

* Three-layers Engineered wood flooring

The Advantages of Engineered Wood Flooring:

- Strengths/ Stability: Engineered wood has stability that forms one of its key advantages. Multi-layer details reduce significantly warping and shifting, especially those that are likely to arise from solid wood-the places where it often happens, like in the basement, kitchen, or very humid areas. This makes engineered wood ideal where solid wood cannot hold up well.

- Versatility: Engineered wood is adaptable to various locations, apart from highly moisture-exposed rooms. It is also suitable for installation over radiant heating systems that might make solid woods crack or warp. This versatility is one of the key benefits to homeowners seeking to install wood flooring in less-than-traditional areas of a residence, such as basements or bathrooms.

- Ease of Installation: The installation options for engineered wood flooring are several, with systems like click-lock that will allow floating installations. In general, these installations are also much quicker and far easier in comparison with nailing down solid wood. This is one more reason that many people love it and also one that can be recommended for DIYers. Due to its design, it can be installed on top of a range of subfloors, such as concrete, without any additional underlay.

The Disadvantages of Engineered Wood Flooring:

- Limited Refinishing: The top hardwood layer in an engineered wood is typically thin compared to solid wood. As such, it can be sanded and refinished only a few times—generally once or twice, largely depending on wear layer thickness. This may not be an issue of concern to most of the homeowners; however, this could be a good point to consider since you are mostly staying for decades in your house and might want the option to brighten your floors every now and then.

- Perceived Value: Engineered flooring is often perceived by homeowners to not offer the same value as solid wood for the long term since this flooring type may not be refinished more than a couple of times, or because it uses non-hardwood materials in making the product. While it’s a highly superior product, it may not entail quite the prestige or perceived longevity as a solid hardwood floor does.

What is Solid Wood Flooring?

Solid wood flooring is truly classic, elegant, and durable. Each plank consists of a single piece of hardwood, typically milled with a thickness of 19 millimeters. For centuries, this type of flooring has been utilized and remains a favorite among those homeowners who like the natural beauty and uniqueness that solid wood brings into a home.

Advantages of Solid Wood Flooring:

- Longevity: Solid wood flooring is highly durable. It is made of one piece of wood, which can be recycled as many times as possible through sanding and refinishing during its lifetime, often to up to 10 or more, depending on the thickness of wood. This means that solid wood flooring is able to last for decades, even centuries: truly an investment in your home.

- Natural Beauty: The richness of natural beauty lies in the fact that each plank of solid wood flooring is different, containing its grain patterns, knots, and coloration; all these aspects combine to create one of the numerous reasons much value is put on solid wood. It offers richness and depth simply not provided by synthetic materials. It even develops, over time, patina-a soft sheen that improves its appearance and adds character to your home.

- High Resale Value: Houses featuring solid wood flooring tend to fetch higher resale values due to the perceived quality and longevity of the material. This is simply because prospective buyers are very pleased to spend more on homes with solid wood floors, knowing full well that they are getting a very enduring and long-lasting product that they can refinish and customize according to their taste.

Disadvantages of Solid Wood Flooring:

- Moisture Sensitivity: Solid wood is more sensitive to moisture and temperature influences compared to engineered wood. Under highly humid environments or in rooms exposed to water, like bathrooms or basements, solid wood could undergo expansion, contraction, or warping. Risk for these is minimized by installing the solid wood in climate-controlled locations and solid wood should be acclimated before installation.

- Higher Cost: Solid wood flooring can blow out a little more compared to engineered wood in terms of material costs and installation. More labor-intensive as well, mostly requiring professional expertise in ensuring the flooring will lay correctly and perform well over time.

Key Differences Between Engineered Wood and Solid Wood Flooring

These are some of the factors that customers have considered from the many years of experience between engineered wood and solid wood flooring. critical differences that will enable you to make the most suitable decision on what to use in your home are discussed below.

1. Strength and Durability:

- Engineered Wood: Engineered wood is created to be as stable as possible. This multi-layered process creates an insult to warping or shifting due to constantly fluctuating moisture levels. Though it can be sanded and refinished, it has a shorter life compared to solid wood because of the thin wear layer it possesses.

- Solid Wood: Solid wood flooring is of an exceedingly long life; it endures well with repeated sanding and refinishing, and, with good care, it is capable of lasting a lifetime. This is probably one of the best long-term investments one can make in a private home where extensive usage will be daily.

2. Aesthetics and Appearance:

- Engineered Wood: The range of engineered wood has many different styles and finishes. It much resembles the appearance of solid wood. It gives a more uniform look, and fewer seams in general are visible. This can be quite appealing in a modern setting or with minimalist decor.

- Solid Wood: provides a rich, authentic look that can’t be replicated by common engineered wood, as each plank features its unique grain pattern and color variation. A patina is developed in solid wood floors over time, which deepens the beauty and character of the floors naturally.

3. Installation Process:

- Engineered Wood: The installation method of engineered wood is, for the most part, quicker and easier – especially floating floor systems – compared to solid wood. This is attributed to the fact that it is ideal for DIY projects or installing over existing subfloors, including concrete.

- Solid Wood: Solid wood flooring is normally installed using a more difficult process, often nailing or stapling the planks into a plywood subfloor. This allows for a secure and long-lasting fit but usually requires professional installation for the best outcome.

4. Maintenance and Refinishing:

- Engineered Wood: Engineered wood is tough, though it resists the daily wear and tear. The refinishing options become limited due to the fact that the layer of hardwood in engineered wood is thinner. It can be sanded and refinished once or twice according to the size of the wear layer. However, this should be enough for any homeowner.

- Solid Wood: Solid wooden flooring can undergo sanding and refinishing many times, a benefit for such homeowners who wish to have new-looking floors for decades. In this connection, it offers an attractive benefit to the homeowners anticipated heavy foot traffic or in case they may want to make changes to the stain color sometime later.

5. Cost:

- Engineered Wood: Generally, engineered wood costs less compared to solid wood. Homeowners on a tight budget with a desire for the appearance of wood prefer engineered wood. Price is determined by the quality of materials and thickness of the top hardwood layer but often provides good value for money.

- Solid Wood: The cost of solid hardwood flooring is higher to purchase and install. However, solid wood can be refinished many times and is extremely durable, which often makes it cost-effective to use over the long term—especially when homeowners plan to stay in the home for decades.

6. Height Requirements and Subfloor Compatibility:

- Engineered Wood: Engineered wood has a thinner profile compared to solid wood, which becomes advantageous in cases in which the height of a project needs to be curbed, for example, renovations of doors or cabinetry where the height is already installed. Can be installed with different subfloors, even concrete.

- Solid Wood: Solid wood is thicker, and installation requires accommodation of doors, baseboards, and trims. It is installed above plywood subfloors and is not recommended above concrete, absent proper preparation measures.

7. Installation Speed:

- Engineered Wood: The floating installation method of engineered wood floors is relatively quicker and reduces the overall time taken for installation. This may be very instrumental in renovation projects where one will wish to minimize the downtime.

- Solid Wood: Installation solid wood flooring requires more time to install, as nailing and stapling need to be done with accuracy. Further, solid wood often needs to sit in the room it is going into so that it acclimates itself to the ambient; this, in turn, might take up some extra time.

8. Warranty and Quality Assurance:

- Engineered Wood: Many types of engineered wood products have 15-30-year warranties; some are as high as 30 years, based on the company and quality of product. Most will cite both structural integrity and an expectation of the finish in such a warranty.

- Solid Wood: The huge solid wood floors have similar or even longer warranties, especially if the quality of the wood is very high and professional. The warranty for solid wood could go up to 50 plus years, covering structural aspects and finish

Recent Trends in Wood Flooring

As the wood flooring industry evolves, a variety of trends have begun to come through in the choices that are made by homeowners:

1. Wide Plank Flooring: Wood flooring in wide planks is quite a thing these days, all because larger areas look commodious and modern.

The wider planks can help pull a room together and often enhance the natural beauty of the wood grain. This trend is especially popular in open-plan living spaces where the flooring can create a seamless flow between different areas.

2. Light-Coloured Wood Flooring: Light shades, such as whitewashed, blonde, and light grey tones, become more popular, as homeowners grow fond of minimalistic and Scandinavian design aesthetics.

Such colours provide openness to the area and lighten it up, while offering versatility with any style of interior. Light-colored floors are also practical-they show less dust and scratches compared to the darker floors that work in busy homes.

3. Textured Finishes: There is a greater demand for textured finishes in woods, be it hand-scraped, wire-brushed, or distressed wood. As a result, such texturizing adds the character to the inlay and injects one sort of rustic charisma into an inlay, providing a unique quality to each floor.

Textured wood flooring fills the bill for hiding the scratches and dings, as imperfections blend in with the natural texture of wood.

4. Sustainable & Eco-Friendly Options: In view of the problem at hand, many property owners are going green with wood floorings. This includes choosing various types of wood that come from well-managed forests, reclaimed wood, or wood flooring made with friendly finishes and adhesives to the environment.

Sustainable wood flooring reduces environmental impact but also appeals to environmentally conscious consumers looking to make responsible choices for their homes.

5. Matte and Low-Gloss Finishes: Moving more and more into matte and low gloss simply because they are so much more trend forward and understated than what has been used over the last decade in particular—the move from the super touristy high-gloss finish to a subtle matte or low-gloss finish.

They are weakly reflective and hence work well in places where the house is exposed to a lot of natural light. Conversely, they tend to reveal fewer scratches and flaws, which helps in areas of high use.

Conclusion

Engineered wood is a better option than solid wood, or vice versa. It depends on your life-style, budget, and surely unique conditions found in your house. Engineered wood boasts stability, versatility, and ease of installation.

It meets requirements in almost any environment. On the other hand, solid wood can boast incomparable beauty, durability, and multiple re-sanding/re-finishing, making it an investment for ages.

Besides these factors, recent trends in wood flooring—wide plank designs, light colours, textured finishes—offer exciting options to beautify and make your space feel just about perfect.

Engineered and solid wood floors in an array of premium options are available at FLOORCO to suit just about any need.

References

- National Wood Flooring Association (NWFA). (2023). Understanding the Differences Between Engineered and Solid Hardwood Flooring. Retrieved from www.woodfloors.org

- Xian-qing, X., Ying-ying, Y., Yi-ting, N., & Liang-ting, Z. (2019). Development of a cornstarch adhesive for laminated veneer lumber bonding for use in engineered wood flooring. International Journal of Adhesion and Adhesives, 94, 80-86. https://www.sciencedirect.com/science/article/abs/pii/S0143749619302866?via%3Dihub

- Consumer Reports. (2023). Durability and Maintenance of Hardwood Flooring. Retrieved from www.consumerreports.org

- Architectural Digest. (2023). Wide Plank Wood Flooring: A Growing Trend in Home Design. Retrieved from www.architecturaldigest.com

- The Guardian. (2023). The Rise of Sustainable and Eco-Friendly Wood Flooring Options. Retrieved from www.theguardian.com

- Environmental Health Perspectives. (2023). Sustainable Timber and the Environment: Best Practices for Wood Flooring. Retrieved from www.ehp.niehs.nih.gov

- Weigl-Kuska, M., Kandelbauer, A., Hansmann, C., & Müller, U. (2023). Wood—From natural color patterns toward naturally altered color impressions. In C. Stevens, T. Bechtold, A. Manian, & T. Pham (Eds.), Advances in Sustainable Materials and Technologies (Chapter 22). Wiley. https://doi.org/10.1002/9781119811749.ch22