Description

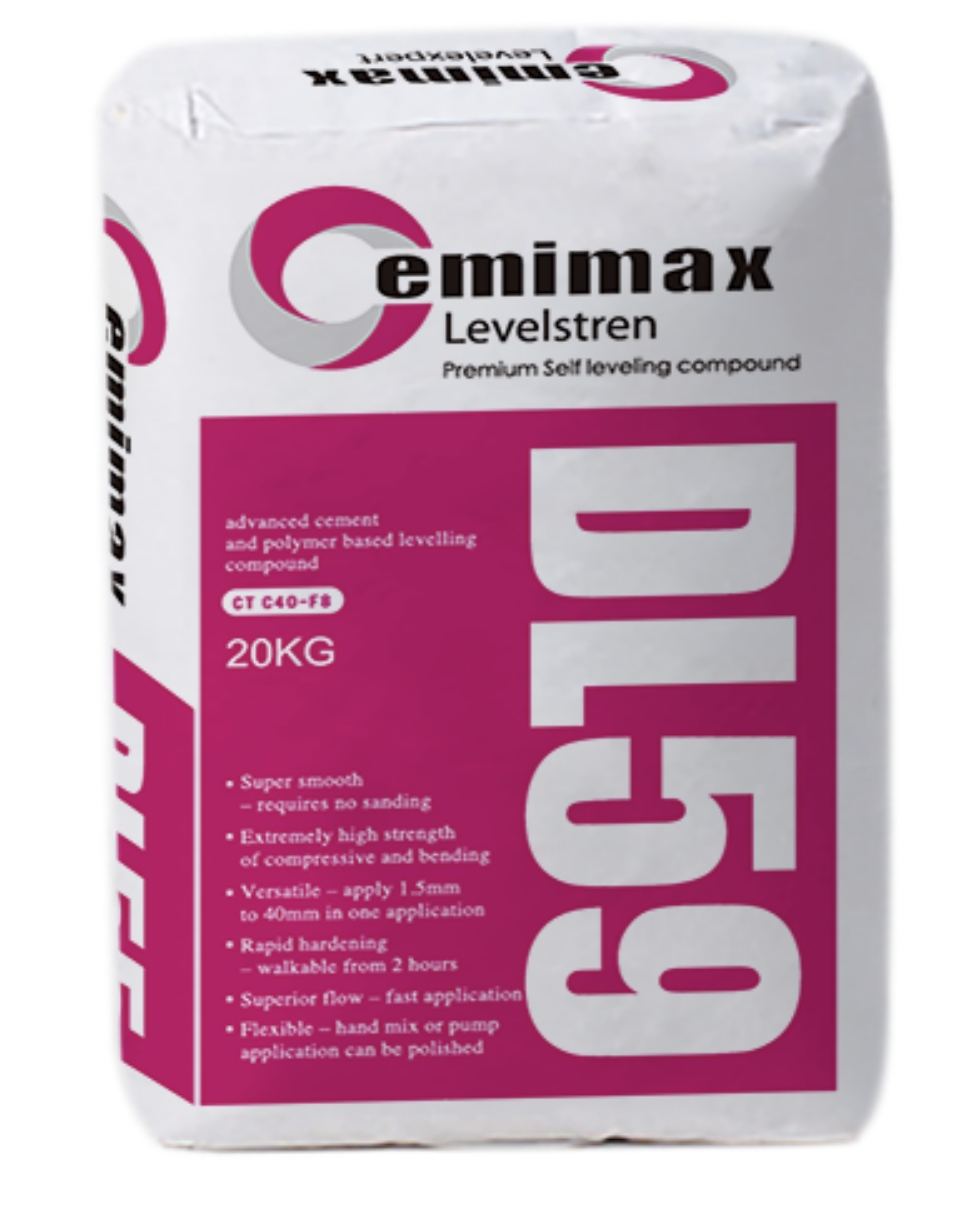

Cemimax DL59 is a cement based leveling compound with very high compressive strength to C40. DL59 is especially suitable for high traffic, heavy wear locations. DL59 can be also used as overlays for polished concrete finishes.1.5mm – 40mm in one application with a 40MPa rating.

The Perfect Floor Self Levelling Compound for Concrete, Tiles, Screed, Plywood & Timber Subfloors. Also the perfect application for outdoor areas + wet areas.

KEY FEATURES:

✔ 1.5mm – 40mm in one pour

✔ Suitable for all floorcoverings

✔ 40MPa rating

✔ Indoors + Outdoors Application

✔ Designed for heavy traffic (Carparks, Warehousing, Balconies, Shopping Centres etc)

✔ Can be polished

✔ Can add stones or colours tothe compound

✔ Highly Flexible compound

✔ Walkable in 2hours

✔ Suitable for underfloorheating

✔ 5m2 @ 3mm thick approx coverage

✔ Best Price in the market

✔ Rated by leading commercial construction companies, view our projects supplied via our website!!

PRODUCT PROPERTIES/BENEFITS

Plastic dry cement mortar with finely graded fillers. When mixed with water, produces a hydraulic-setting smoothing compound with good flow properties and high coverage.COMPOSITION

Special cements, mineral fillers, polyvinyl-acetatecopolymers, flow agents and additives.

• Super smooth – requires no sanding

• Extremely high strength of compressive and bending

• Versatile – apply 1.5mm to 40mm in one application

• Rapid hardening – walkable from 2 hours

• Superior flow – fast application

• Flexible – hand mix or pump application

• Can be polished

• C40 flex – 60%

TECHNICAL DATA

Compressive Strength

After 1 day approx. 15MPa

After 7 days approx. 25MPa

After 28 days approx. 40MPa

Tensile Bending Strength

After 1 day approx. 5MPa

After 7 days approx. 7MPa

After 28 days approx. 10MPa

Pack-size: 20kg/bag

Shelf-life: 6-12 months

Coverage: Approximately 5m² at 3mm thick

Dry time: 2hrs

Working time: 20-30mins

THICKNESS

DL59 can be applied from 1.5mm to 40mm thickness in one application.

SUBFLOOR PREPARATION

• The substrate must be sound, free from cracks, dry, clean and free from materials which would impair adhesion.

• Test the substrate according to applicable standards and report any deficiencies.

• Brush, abrade, grind or shot-blast any weak surface sections or areas which will not accept adhesion.

• Thoroughly vacuum to remove loose material and dust

• According to type and condition of the subfloor, use suitable Cemimax primer.

• Allow primers to dry thoroughly.

APPLICATION

1. Put 4 – 4.4litres of cold clean water into a clean container. Sprinkle in the sack contents (20kg) whilst stirring briskly and mix to a thick-fluid. Lump-free consistency. Use a drill or mixer fitted with a Mixing Paddle. Do not mix too thinly.

2. Pour the mixture on the area to be applied, spread the material uniformly to required thickness using toothed rake. It is the next step to remove entranced air by particle roller.

3. Drying time at 20°C is approx 24 hours. Abrading using 40-60 grit sanding paper improves both the surface quality and the absorbency. Poor air-flow and lower temperatures will significantly affect drying times.

Cemimax DL59 Leveling