Manufactory accepted product tolerance , upon and down warping, edge damage( not damage surface & Décor ) and some of unqualified product. The tolerance inclusive edge, thickness , width, T&G etc.

|

Products tolerance |

warping |

Edge damage |

Unqualified |

|

≤0.15mm |

<15% of length |

<0.5% of length |

<0.3% |

|

Colour variation |

Sapwood (white of edge) |

Color change |

Knots & wood grain |

|

Accept |

By Design |

Accept |

By Design |

The first laminate floor was developed in 1977 in Sweden, The laminate of the early years was not of the high quality that it is today – but thanks to on-going developments, by the end of the 1980s visible advances had been achieved.

Today laminate is one of the most popular floor surfaces in the world

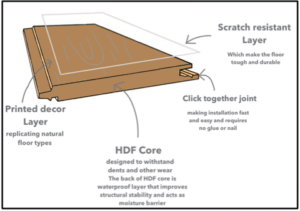

The general composition of laminate is composed of three layers.

Layer 1:

First, the uppermost laminate layer consists of an overlay to protect against wear and tear and a design layer, which depending on the production process is made from one or several layers. The surface coating is composed of a special synthetic resin-treated cellulose to give the floor a tough, durable surface. The decorative layer gives the laminate flooring an attractive appearance.

Layer 2:

Under the decorative pattern is the wooden composite core (HDF).

Layer 3:

At the base on the back of the HDF core you will find a watertight layer that improves the structural stability and serves as a moisture barrier. All three layers are permanently bonded with resin, heat and pressure.

The base layer of laminate is an impermeable, layer underneath the base that improves its structural stability and serves as a moisture barrier. The thick, middle layer is a wooden composite base. The topmost layer of laminate flooring is the wearing surface and the decorative layer that, depending on the production process, can consist of several layers. It consists of a special resin-treated cellulose and gives the floor a tough, durable surface and makes it visually attractive.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed non risus. Suspendisse lectus tortor, dignissim sit amet, adipiscing nec, ultricies sed, dolor.

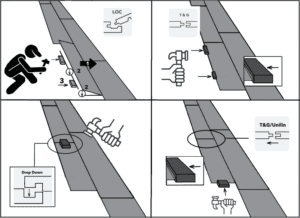

Click Laminate is a type of flooring that employs a glue-free connection and, in comparison to conventional flooring, has many advantages for installers. A special profile on the edge of boards, called tongue and groove, allows adjacent boards to snap together for a tight fit without the need for an adhesive. The easy installation and lack of drying time can decrease installation time by up to 50%. This type of flooring is also reusable, meaning that sections can be removed and re-installed elsewhere without damaging the individual boards. The tight-fitting tongue and groove profile of the floorboards ensures that there will never be gaps between two pieces.

The core layer of laminate flooring consists of one of a variety of wood-based composites used to support the outer layers. These layers can be laminates or different types of veneers. HDF boards are commonly used in laminate flooring production and range from 6 to 8mm in thickness. Click Laminates have a core layer that is made with a higher amount of resin and therefore resist moisture effectively. Chipboard does not have the same technical characteristics, cannot handle the same loads, and is more difficult to install than HDF boards, clearly making them inferior and numbering the days until chipboard is no longer the market leader.

Décor paper is a combination of protective coating and faux wood design, such as beech or maple, used to cover laminate flooring. This printed-paper is impregnated with resin, heated, and firmly pressed onto the topside of laminate flooring sheets.

HDF is a type of wood panel that is made from wood fibres. These panels are mainly used as a substrate for laminate flooring as they have a very homogenous structure and non-porous surface. HDF can, therefore, be directly printed upon, painted, or sealed. In comparison to MDF or chipboard, HDF boards have a higher density, which in turns means they have a higher tensile strength. These boards are also much more resistant to swelling and deformation. MDF and HDF are very aesthetically similar.

Unlike parquet or veneer flooring, the surface of laminate flooring is not comprised of a coating of oil or wax applied to wood. Laminate flooring has a thin top layer of resin-impregnated paper (usually melamine resin), which is called the overlay. Together with the décor paper, the overlay is pressed on the backing layer, usually made of HDF.

During the fusing process, the resin-coated overlay is pressed onto the backing layer using high pressure and heat, creating a solid, sturdy surface.

This is a collective term applied to various types of products formed by compressing wood chips or fibres with the aid of glue or resin.

This is the rating according to DIN 4076 Part 5 for flame-resistant building materials. The DIN ratings for semi-flammable and highly flammable are B2 and B3, respectively.

This is the symbol to indicate emission class. The emission classes denote the amount of formaldehyde released from wood-based materials. This distinction is made between classes E1, E2, and E3, with the class E1 having the lowest amount of emission. Classes are assigned based on testing. In this scenario, a test piece of wood is subjected to moving air kept at a constant temperature inside of a testing room. The amount of formaldehyde that is released is then measured and given a value in parts per million (ppm). This value must not exceed 0.1 ppm. Common laminate flooring contains such a small percentage of contaminants that they are generally labelled as ‘contaminant-free’.

This is a colourless, pungent-smelling gas. Formaldehyde is a prime component of the resins used in the production of synthetic wood products, such as laminate flooring and chipboard. Irritation of the eyes, mucous membranes, and respiratory tract are all caused by exposure to formaldehyde. The upper limits of formaldehyde emission are between 0.2 and 0.1 ppm (parts per million). Due to increasingly more stringent regulation, the amount of formaldehyde that can be used in resins during laminate flooring manufacturing has been restricted to the point where flooring can generally be labelled as ‘formaldehyde-free’.

All the floors at Floorco can used for underfloor heating either hot water or electric heating system. While the surface temperature of the laid flooring must not exceed 27 ℃ permanently

Yes, laminate flooring is very easy to install. But it is important to talk with one of our consultants first.

Yes we do.

Normally it takes one day for a less than 30 sqm area, if need extra preparation for the subfloor such as levelling or sanding, removing existing floor covering, taking off skirting boards will take 0.5 to 1 day for a 30sqm area.

If you choose a glue-down method, it will cost double time than floating method because of the waterproofing process and the installation.

looking for laminate flooring north shore and Auckland.

STEP CASA SC03 beautiful flooring – Jeffs Road, Flat Bush

“beautiful laminate flooring at lowest price in New Zealand!” – F.N. home owner The light grey floor is one of […]

Krono 8155 Appalachian hickory-Alexandra St, Riverhead

” VINTAGE CLASSIC , Krono 8155 Appalachian hickory laminate floors is real wood looking ” – B.P home owner A […]

LOFT DESIGN- DARK GREY LAMINATE FLOORING

LOFT DESIGN- DARK GREY LAMINATE FLOORING IS HIGHLY WOOD EFFECT, Auckland supplier. The Dark grey floor is one of the […]

Exquisite workmanship and moisture defense Binylpro laminate flooring

Exquisite workmanship and moisture defense Binylpro laminate flooring. Oak nature color is the most popular color in the world. Of […]

12mm fast DIY laminate floors are Captivating Looking

Captivating Looking and fast DIY laminate floors covering The light gray floor is one of the most popular colors in […]

Luxury of laminate flooring

Luxury of gray binylpro laminate flooring New Zealand The light gray floor is one of the most popular colors in […]

Beautiful of boulder oak laminate flooring

Beautiful of boulder oak laminate floor covering, Krono high quality flooring made in Germany, Nordic Modern gray. The light gray […]

Misunderstanding of floorboard

Misunderstanding of laminate, wood and spc flooring. The customers often fall into the following three misunderstandings when they buy the floorboard. […]

Best laminate floorboard brands

Krono original laminate, Swiss Krono,Quickstep,Pergio,Haro,Berry and Wineo Krono original Krono original is an international company – Kronospan’s laminate floors brand, Kronospan […]

How to deal with the uneven sub-floors?

Flooring leveling, Preparation sub-floors, Wood flooring prepare, Nowadays, some customers prefer to do flooring installation (DIY) in their spare time, […]